Specialized Processes

Specialized Processes (PDF), (Somali PDF), (Spanish PDF), are processes or procedures requiring specific food safety controls not otherwise assessed in the Minnesota food code.

Specialized Processes Include:

- Reduced oxygen packaging (ROP)

- Smoking

- Curing food

- Using food additives to make a food shelf stable

- Operating a molluscan shellfish tank

- Sprouting seeds or beans

- Preparing food any other way not described in the food code

Specialized processes conducted in a retail food establishment require a preapproved Hazard Analysis and Critical Control Point (HACCP) plan. Often, a variance is also required.

What is HACCP?

HACCP is a preventive and systematic approach to food safety. It identifies food safety hazards (biological, chemical, and physical agents) in the food production process that are reasonably likely to cause illness or injury in the absence of their control. A HACCP plan provides the steps needed to reduce those hazards to a safe level and a method to initiate corrective actions if a hazard occurs.

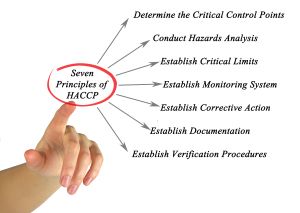

“HACCP plan” means a written document that outlines the formal procedures for following the Hazard Analysis and Critical Control Point principles. These principles, or steps were developed by The National Advisory Committee on Microbiological Criteria for Foods.

What are the seven principles of HACCP?

What are the seven principles of HACCP?

Using these seven principles, the HACCP plan identifies and addresses critical control points, commonly referred to as CCPs, where illness or injury is reasonably likely to occur in the absence of the hazard’s control. Annex 5 in the FDA Food Code 2013 contains HACCP guidelines and annex 6 contains food processing criteria.

What is included in a HACCP Plan?

The following are essential components that are needed for a HACCP plan to be approved by the MDA. If items are missing it can slow the review process and hold up a food establishment from being able to conduct their intended processes.

- Food establishment name and address to include a HACCP point of contact (phone and email, if available)

- Equipment list

- Recipes or formulations (including the name of cure and percent nitrite)

- Food products that will be made using the specialized processes

- Flow diagram identifying Critical Control Points (CCPs) for each process

- Standard operating procedure for each process

- Hazard Analysis (identify the significant hazard such as biological, chemical, or physical)

- List CCPs for the process

- Listing critical limits (ex. cooking temperatures, cure amounts, and cooling temperatures)

- Verification procedures for each Critical Control Point. (Include how the Critical Control Points are monitored and the frequency.

What is the process to submit a HACCP Plan for review?

For the fastest service and best results, it’s recommended to work directly with a HACCP consultant to build a plan before submittal. The HACCP consultant will go through the specialized processes being conducted and identify what components of the plan the food establishment needs.

The consultation between the food establishment and the MDA HACCP team member can be done in person, by phone, email, or a combination of all three. This process may start with a meeting that will take a few hours or more but will reduce the overall review time for the business.

Once the HACCP plan is built and both the food establishment and HACCP team member agree on all the components, an approval letter is issued to the food establishment and any necessary specialized process variances are approved. HACCP plans that have been completed and reviewed by the MDA staff must be kept on-site and available for the area inspector to review during inspections.

If you wish to conduct any specialized processes within your food establishment, please reach out to the HACCP team at MDA.HACCP.Variance@state.mn.us or 651-201-6194.

Multiple specialized processes at a single food establishment

A food establishment might conduct multiple processes that require a HACCP plan. Each process will have its own HACCP plan. The process to submit each plan is the same, and the HACCP consultant will organize the information provided into a separate HACCP plan. This allows the food establishment to add or remove a HACCP plan from their operation easily without modifications to existing HACCP plans.

Multiple food establishments under a single HACCP plan

A parent corporation may submit a single HACCP plan on behalf of several stores, provided all stores conduct the same processes and have the same procedures. Additionally, all stores must be under the jurisdiction of the MDA and with locations clearly identified. Stores falling under the jurisdiction of delegated agencies must have HACCP plans submitted to those agencies for review.

Specialized process variance

Most HACCP plans require a specialized process variance to conduct the associated activities within the food establishment. The MDA HACCP Team or Retail Inspector will work directly with the food establishment to approve and renew the specialized process variance.