Food Safety Tips for the Holidays

Don't forget to add Food Safety to your holiday "To Do" list. The United States Department of Agriculture (USDA) and the Federal Food and Drug Administration (FDA) recommend four steps to keeping food safe this holiday season and throughout the year:

Don't forget to add Food Safety to your holiday "To Do" list. The United States Department of Agriculture (USDA) and the Federal Food and Drug Administration (FDA) recommend four steps to keeping food safe this holiday season and throughout the year:

- Clean your hands for 20 seconds with soapy water. Always serve food on clean plates and avoid reusing plates that previously held raw meat and poultry.

- Separate raw and cooked foods so you don't cross contaminate.

- Cook using a food thermometer to make sure food reaches a safe minimum internal temperature.

- Chill leftovers within two hours of cooking. Keep track of how long items have been sitting on the buffet table and discard anything that has been out longer than two hours.

Visit Food Safety Tips for the Holidays for more helpful information.

Foodborne Illness Risk Factors

The Centers for Disease Control and Prevention (CDC) research indicates there are certain practices that contribute to most foodborne illness outbreaks. These practices fall into five broad categories known as foodborne illness risk factors. They focus on areas including:

Systematically reducing the occurrence of these risk factors reduces the risk to food safety and consumer health. Click on each risk factor to learn more about what it covers, why it’s a concern, and how to reduce its occurrence.

Risk Factor: Employee Health and Hygiene

Most foodborne illness outbreaks are associated with food worker health and hygiene. This indicates more training and resources are necessary to address prevention of foodborne illnesses.

Employee Illness

Employee Illness

A foodborne illness is caused by ingesting food that has been contaminated with germs or toxic substances and can sometimes be life threatening. Symptoms can include nausea, vomiting, diarrhea, or fever and can occur within hours or days after consumption of the contaminated food.

Preventing food workers from handling food when they or a family member is ill can prevent a foodborne illness outbreak.

The symptoms below must be reported to the Person In Charge (PIC) at the food establishment and the affected food workers must be excluded from working with food:

- Diarrhea

- Vomiting

- Jaundice (yellowing of the skin and eyes)

- Sore throat with fever

- Open infected wound

Reporting

The food establishment's PIC is responsible for reporting symptoms and confirmed cases of foodborne illnesses to the regulatory authority or licensing entity. A helpful way to remember the foodborne illnesses that must be reported is the acronym HENSS which stands for:

- Hepatitis A virus

- Shiga toxin-producing E. coli

- Norovirus

- Shigella spp.

- Salmonella spp.

Reporting a Suspected Foodborne Illness

The Minnesota Department of Health (MDH) manages foodborne and waterborne illnesses. To report a suspected foodborne or waterborne illness you can:

- Call 1-877-FOOD-ILL (1-877-366-3455) from within Minnesota

- Submit your report using the Foodborne and Waterborne Illness Report, a confidential online survey

- Or email health.foodill@state.mn.us

Visit Reporting Suspected Foodborne and Waterborne Illness for more information.

Returning to Work

Employees must be symptom free for 24 hours prior to returning to work. This means an employee experiencing illness on a scheduled day off may still be required to report symptoms to the person in charge if they are scheduled to return to work before they have been symptom free for at least 24 hours.

It can be confusing to determine when a food employee can return to food handling practices as some symptoms can occur for other reasons beyond a foodborne illness. Utilize the illness symptoms action guidance chart (PDF) to help make the appropriate determination. It lists illnesses/conditions, the action food workers should take and the criteria for returning to work.

Creating an Employee Illness Policy

All food establishments must have an employee illness policy and it’s encouraged to have this policy in writing. The policy needs to include:

- Reportable symptoms and the five foodborne illness diseases (HENSS),

- What to do when food employees experience reportable symptoms,

- What to do if an employee test positive for a reportable disease (HENSS):

- Hepatitis A virus

- Shiga toxin-producing E. Coli

- Norovirus

- Shigella spp.

- Salmonella spp.

- When employees are allowed to return to food handling tasks

The food establishment should have a system to train employees, receive notice of illnesses, and track the information.

Training

Training on such an important topic should be done often to ensure staff are knowledgeable and confident on their role and responsibility to report symptoms. The more often employee illness training occurs, the more likely employees are to follow the procedures if they become ill.

Tips for Training

- Post handouts such as Employee Illness Decision Guide (PDF) in places employees gather or stand such as near the handwashing sink.

- Highlight employee illness topics during daily, weekly and monthly meetings. Include food employees and management, reminding everyone of the policy.

- Remind staff seasonally, such as during winter months when norovirus, commonly referred to as the stomach flu, peaks in January and February.

- Upon beginning a shift, create a system to confirm an employee does not have a reportable symptom before handling food. This could be a questionnaire specifically asking about symptoms.

Receiving Notice of an Ill Employee and Tracking Food Employee Illness

The food establishment should designate at least one individual during every shift for food employees to report illness to. They will need to be trained on what information to collect, and what to do with the information once collected.

An illness log is a tool used to document when food employees are experiencing any of the reportable symptoms. This tool can be used to assist inspectors during complaints or outbreak investigations. The lack of an accurate employee illness log can slow the investigation, which may allow additional staff or patrons to get sick.

Tips for Receiving Notice of an Ill Employee and Using an Illness Log

- Use one system throughout the establishment to ensure consistency.

- Ensure the PIC has access to an illness log and that they are aware of their responsibility to properly record the specific reportable illnesses. Writing "sick" is not adequate.

- The log should be located at the establishment and can be made available promptly when requested.

- Use the illness log regularly. If no one has reported an illness, record on the log "no reports for the month".

- Track when an employee is brought back to work after being symptom free for 24 hours.

Personal Hygiene

Handwashing reduces the spread of pathogenic microorganisms transmitted to food when conducted properly and at the right times and locations. Proper handwashing includes using soap and water and rubbing hands vigorously. It must be conducted in a designated handwashing sink that is easily accessible to the food preparation area.

How to Wash Your Hands

- Wet your hands

- Apply soap

- Rub your hands for 10 to 15 seconds

- Rinse your hands

- Dry your hands using a disposable towel

- Use the disposable towel to turn off the faucet

- Keep hands clean

The entire process must last at least 20 seconds. See a video on how to properly wash hands: Hand Hygiene

Gloves, wet-wipes, or hand antiseptics are not substitutes for handwashing, but rather additional tools that can be used. This is because not all hand antiseptics or hand sanitizers are effective at killing viruses such as norovirus. For more information, the CDC explains the science as to why hand sanitizer is not effective.

When to Wash Hands

Refer to the Handwashing for Employees factsheet (PDF), (Hmong PDF), (Somali PDF), (Spanish PDF), for specifics on when to wash hands. Hands should be washed anytime before an employee handles food or clean utensils.

Common Handwashing Violations Include:

- After cracking a raw egg and before handling clean utensils or ready to eat food such as bread,

- After handling dirty dishes and before handling clean equipment,

- Serving food raw animal foods to a customer and moving directly to a ready to eat food such as cooked shrimp with only a glove change.

- Washing hands in a restroom and not washing again when returning to the food preparation area.

Gloves are a tool to prevent the spread of viruses and bacteria from a person to food, by minimizing bare hand contact with foods. However, if gloves are not used properly between different tasks, they can become a source of contamination.

Tips for Success

- Train employees to properly wash their hands and ensure sinks are fully stocked with soap and paper towels. Do routine checks to verify sinks are stocked and ready to go.

- Monitor employees washing their hands. Food employees get busy and don’t always recognize missed opportunities of handwashing. A manager should take time, five to ten minutes during busy times, to observe and make on the spot corrections of employees.

- Pay attention to task changes, as a glove change may not be sufficient. If an employee was handling raw animal foods before handling ready to eat foods, hands must be washed prior to putting on clean gloves.

Risk Factor: Food from Unsafe Sources

Risk Factor: Food from Unsafe Sources

All food is required to come from a licensed entity or an approved source ( English PDF), (Somali PDF), (Spanish PDF), be protected during receiving and at the proper temperatures when received. It can be difficult to determine just by looking at a finished product if it’s approved or not. It is up to the food establishment to inquire with the supplier and verify they are licensed to sell food, as well as inspect each shipment to verify it’s protected and at the proper temperature.

When Receiving Food Products:

- Check temperatures. In most cases:

- Cold time and temperature control for safety foods or TCS food should be 41°F or below

- Milk, shell eggs and molluscan shellfish should be 45°F or below

- Hot TCS food should be 135° or above and

- Frozen food should be frozen solid

- Verify packages are intact and are not torn, dented, or broken.

- Check for pest infested items.

Do not accept products that have been temperature abused or adulterated. Check the Receiving Food Products (PDF), (Somali PDF), (Spanish PDF), fact sheet for more information.

Meat Products

Meat Products

Meat products should have an inspection bug or decal from the USDA or Minnesota's "Equal To" (E2) program when received. Without these decals, the food is likely not approved. For more information refer to the Approved Sources of Meat and Poultry for Food Facilities (PDF) fact sheet.

Shellstock

Shellstock

Shellstock such as clams, mussels, and oysters must have approved tags or labels attached to the product. When shellstock are on display in a seafood case, only one bag of the species can be opened at a time.

- To keep the tags dry when on display, they can be placed in a small plastic bag or wrapped in plastic wrap and stored with the shellstock.

Once the shellstock is sold, the tags must be kept at the food establishment for 90 days in chronological order. Write the date on the tag when the product was last sold.

- Three ring binders or coupon organizers are useful tools to keep tags in order.

Refer to the Molluscan Shellfish (PDF), (Somali PDF), (Spanish PDF) fact sheet for additional information.

Produce

Products of the farm, such as produce or honey, may not require a license if the supplier is the one who grew the products on their land. This is referenced in the Minnesota Statutes as product of the farm. This means retail stores can legally buy products from local farmers that do not hold a license with the MDA. Farmers are an approved source.

This exclusion only refers to the need for a license. Refer to the Selling or Serving Locally Grown Produce in Food Facilities (PDF), (Somali PDF), (Spanish PDF), fact sheet for more information on what requirements are applicable, and other frequently asked questions about product of the farm foods.

Food from a Private Home

Food that is prepared in a private home is NOT an approved source. Registered Cottage Food Producers are allowed to sell certain non-potentially hazardous foods that are prepared in a home or private residence to the end consumer. They are registered, NOT licensed, and therefore cannot sell their products to a retail store for resale.

Risk Factor: Improper Cooking Temperature/Methods

Risk Factor: Improper Cooking Temperature/Methods

Proper hot holding, cold holding, and cooling will limit the growth of bacteria, but it will not destroy them. That is why it is important to cook foods to their proper temperature and for the right amount of time.

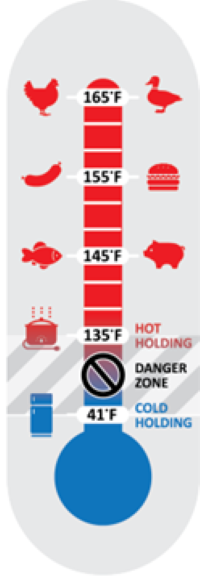

Raw animal foods have different final cook temperature requirements based on their anticipated level of pathogenic bacteria in the raw product. For example, greater numbers of pathogens are found on poultry, thus a higher final cooking temperature is required of 165°F compared to other meats.

It is the responsibility of the food employee to know the safe cooking and reheating temperatures applicable to the operation. Utilize the Temperature and Time Requirements (PDF), (Somali PDF), (Spanish PDF), fact sheet for the specific cooking temperatures.

Reheating Foods

- Ready-to-eat foods made in a food processing plant, opened in the retail food establishment, and reheated must reach 135°F or hot holding.

- Ready-to-eat foods made in a food processing plant that are heated in the retail establishment, then cooled, and reheated again, must be reheated to 165°F.

- Foods that are cooked and cooled in the retail food establishment must be reheated to 165°F for 15 seconds.

These subtle differences can have a big impact on the safety of the food being prepared.

Food operators are encouraged to review the various foods prepared, being mindful of which are raw, partially cooked, or fully cooked. Often the packages will indicate on the label which category the product fits into.

Tips for using thermometers

Take the internal temperature of the food after cooking. Do not rely on the amount of time the food was cooked, or its appearance to know when it is done cooking.

- Take multiple temperatures of cooked foods such as:

- Check several rotisserie chickens that were cooked at the same time and temperature

- Check multiple spots in a pan or pot to ensure the entire batch was cooked thoroughly

- Check the thickest part of the food such as the chicken breast. The thinner areas such as a chicken leg will cook faster

- Wrap or fold the package around the thermometer (sandwich method), for packaged foods such as soups or mashed potatoes before taking an internal temperature.

- Stir the food when possible, to obtain a consistent temperature throughout the food.

- Use a small diameter probe to measure thin pieces of food such as meat patties or fish fillets.

- Provide multiple thermometers that are conveniently stored and accessible to employees.

- Check that thermometers are accurate often. It should read 32°F in ice water if it is calibrated correctly.

- Thermometers must be cleaned and sanitized before they are used in food. Alcohol wipes work well for this.

Risk Factor: Improper Holding, Time and Temperature

"Time/temperature control for safety food (TCS)" means a food that requires time and temperature control to limit pathogenic microorganism growth or toxin formation. Keep refrigerated TCS foods at 41°F or below, and TCS food that is held hot at 135°F or above. Anything in between is often referred to as the ‘Danger Zone’ as harmful bacteria can grow rapidly within this temperature range. Check out the Time/Temperature Control for Safety Food (PDF) fact sheet for an easy reference to print.

Hot Holding: 135°F or above

Hot Holding: 135°F or above

Hot holding units include steam tables, heat lamps, double boilers, or hot holding serving cases. There is no time limit on how long food can be hot held if it is maintained with an internal temperature of 135°F or above. Check temperatures of foods in a variety of locations and be sure to temp foods that are likely the coldest in the hot holding unit, such as:

- The food at the top of an overfilled container.

- Food that is held closest to the door of the serving case or that is next to a cold holding case.

- Certain foods hold their internal heat better than others, so check multiple items.

Cold Holding: 41°F or below

Cold Holding: 41°F or below

Cold holding units include walk-in coolers, prep coolers, cold top tables, refrigerated displays, and refrigerated trucks. TCS food must be held at 41°F or below. Check temperatures in locations that are likely the warmest in cold holding units, such as:

- Along the front of a case or the furthest location from the cold air.

- Food at the top of an overfilled container.

- Food that is held closest to the door of the serving case or that is next to a hot holding unit.

- Certain foods hold their internal temperature better than others, so check multiple times.

Cooling

Foods that are being cooled must do so rapidly to avoid potential bacteria from growing. This is true for both cooked foods, such as fried chicken, and cold foods prepared at room temperature, such as sandwiches or salads. Refer to the Cooling Time/Temperature Control for Safety Food (PDF), (Somali PDF), (Spanish PDF), for an easy printable fact sheet.

Cooling food from hot temperatures must happen quickly because bacteria grow the fastest in between 41°F and 135°F, which is why it’s referred to as the danger zone.

- TCS food must be cooled from 135°F to 70°F within two hours and completely cooled to 41°F or below within six hours.

For example, fried chicken was cooked to 165°F, hot held at 135°F, and cooled reaching 70°F within one hour, the fried chicken now has five hours to cool to 41°F, for a total of six hours.

- TCS food prepared from ingredients at room temperature (70°F), such as salads, sandwiches, or cut melons, must be cooled to 41°F or below within 4 hours.

Suggestions for cooling rapidly:

Use pre-chilled ingredients to prepare foods such as sandwiches or salads. This will decrease the time to cool them from 70°F to 41°F.

Keep prep time short to maximize the time the food has to cool. The longer the food is out of refrigeration, not only does it get warmer, but there is less time to cool the food back down.

Make food in smaller batches. Assembling all the necessary sandwiches or salads at once may seem convenient, but this extends the time the food is out of refrigeration. Focus on a few salads, or one type of sandwich first, then place them in refrigeration before moving on to the next food item.

Leave packages such as salads and sandwiches open while they are cooling to allow air circulation. Once they are fully cooled, seal and label them.

Use shallow (two inches or less) metal pans to allow adequate heat transfer. These pans should be uncovered and spaced apart from other foods while cooling to allow air flow around the entirety of the pan, and to prevent foods nearby from warming up.

Stir hot foods often.

Initiate cooling in a walk-in freezer for rapid cooling.

Cool food in walk-in units, verify the cooler temperature is below 41°F.

Datemarking

Not only is temperature a factor in keeping TCS foods safe, but so is time. For ready-to-eat (RTE) TCS foods datemarking is required to ensure the food is not used past seven days once it is opened or prepared. Datemarking helps control the growth of microorganisms, such as Listeria, which if present, can grow in refrigerated environments. That is an example of why it is important to limit the amount of time foods are held in the retail establishment. Check out the Date Marking (PDF), (Somali PDF), (Spanish PDF), fact sheet for an easy reference to print.

Suggestions for datemarking:

Suggestions for datemarking:

- The day the food is prepared is day one. Add six days to the date label for a total of seven days the TCS food can be used.

- Train food employees to mark foods using the same method to clearly indicate "open" versus "discard" on the packages.

- If it’s unclear whether a food requires datemarking, check the Minnesota Food Code or ask your inspector. All open or prepared RTE TCS foods are required to have a datemark unless specifically excluded.

Risk Factor: Contaminated Food/Equipment

Cross contamination is the unintentional transfer of bacteria from one surface to another surface. This could be from unclean hands or equipment that touch food, or from raw animal foods that touch or drip onto foods that are ready-to-eat (RTE). To prevent cross contamination, food must be handled safely during receiving, storage, preparation, and display. There are three main methods food becomes contaminated, they are:

- Contamination from food including raw animal food or raw, unwashed produce,

- Contamination from the environment such as dirty food contact surfaces (knives, cutting boards, slicers, etc.),

- Contamination from a food employee’s soiled hands or gloves.

Tips for preventing cross contamination during production:

- Wash hands after handling raw animal foods or touching unclean surfaces.

- Use gloves for one task and remove them after handling food and before handling clean equipment. For more information refer to Preventing Contamination from Hands (PDF), (Somali PDF), (Spanish PDF) fact sheet.

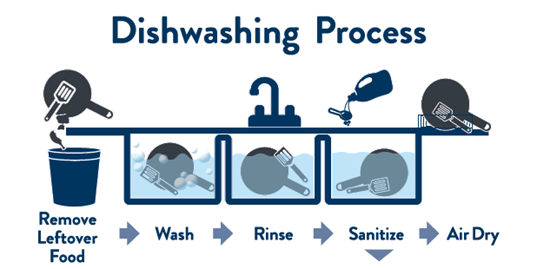

- Wash, rinse, and sanitize equipment between handling different raw animal species such as beef, pork, and poultry, and in between handling any raw RTE foods and RTE foods. Check out the Cleaning and Sanitizing (PDF), (Somali PDF), (Spanish PDF), fact sheet to learn more about the cleaning process.

Consider the production order. Plan to start production with foods that don’t require cooking, moving to foods that require the lowest cooking temperature, and ending with preparing foods that require the hottest cooking temperature. For example, start with RTE foods, then move on to fish, then beef and pork, followed by ground beef or ground pork, and end with poultry.

- Color code equipment such as cutting boards to know which food item is designated for that equipment. An example is green cutting boards are only used to cut produce and white cutting boards are used for sandwich making.

- Dedicate specific areas for tasks and do not use them for any other purposes, such as a raw chicken prep space.

Tips for preventing cross contamination during storage:

- Use dividers or barriers in display cases that prevent leaking or spilling onto other foods.

- Store RTE food on the top shelves or displays with food that requires a hotter cooking temperature on the shelves below. Poultry requires the hottest cooking temperature and therefore it should be stored on the bottom shelf.

- Chemicals must be below or away from food and food containers.

- Foods should be covered when not actively cooling to prevent contamination.

Contaminated Equipment

Food contact surfaces are required to be properly cleaned which includes a wash, rinse and sanitize step. When equipment or utensils are not cleaned properly, they can become a source of contamination.

Food employees must know when and how to effectively clean and sanitize food contact surfaces, this includes knowing how to check the strength of the chemical sanitizer or the temperature of the hot water sanitizer.

Equipment that touches RTE TCS foods is required to be cleaned at a minimum of every four hours. For alternate cleaning frequencies in refrigerated spaces, refer to the Minnesota Food Code for the time and temperature parameters. If one of these options is used, a log to record the temperature of the room is required.

Tips for cleaning equipment:

- If using a chemical sanitize method, food employees must know how to use the test strips. Follow the directions on both the sanitizer and test strips.

- For dishwashers that use heat as the sanitizer, such as a mechanical dishwasher, a waterproof thermometer or gauge is necessary to check the proper surface temperature of 160°F was reached.

- For difficult to clean items such as a meat tenderizer, place them in hot soapy water immediately after use to prevent food from drying on the equipment.

- Inspect equipment before it’s used to check for cleanliness. The use of a flashlight on equipment such as slicers, band saws or grinders can help to see food that is not easily visible.

- Use a timer or log to remind food employees when the equipment is due to be cleaned.

- For equipment that cannot be placed in a 3-compartment sink, three buckets may be helpful to complete the wash, rinse, sanitize steps.