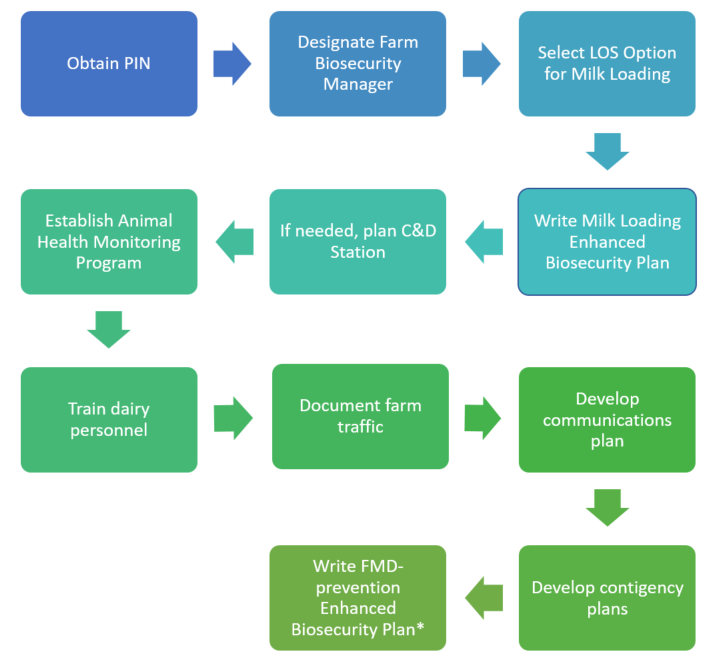

The flowchart below summarizes the steps a producer follows to participate in the Minnesota SMS Program. All of these steps can be completed in advance, so the measures are ready to be implemented in the event of an outbreak. Details for these steps are provided below and in the Biosecurity Plans section.

Abbreviations

PIN: National Premises Identification Number, obtained through the MN Board of Animal Health

LOS: Line of Separation, an outer control boundary that separates on- and off-farm traffic

C&D Station: Cleaning and Disinfection station for milk trucks crossing the LOS

There are 10 main steps to participating in the Minnesota SMS Program : 1) Obtain a Premises Identification Number; 2) Designate a farm biosecurity manager; 3) Select a Line of Separation option for milk loading; 4) Write a milk loading enhanced biosecurity plan; 5) If needed, plan a cleaning and disinfection station; 6) Establish an animal health monitoring program; 7) Train dairy personnel; 8) Document farm traffic; 9) Develop a communications plan; and 10) Develop contingency plans. An 11th step is strongly recommended, and that is to write an FMD-prevention enhanced biosecurity plan that will help protect the herd from FMD.

Producer Guidelines for Milk Movement

Introduction

Controlling the movement of animals and animal products is critical to prevent the spread of Foot and Mouth Disease (FMD) from infected to non-infected premises. Movement control is accomplished through a permitting process, which allows products to move without creating an unacceptable risk of disease spread. This process is determined by the responsible regulatory officials. For dairy premises located within a disease Control Area during an FMD outbreak, permits may be required to move raw milk from dairy operations to milk processing plants.

Permit Guidance (Steps to Move Milk)

Regulatory Officials will require that each of the steps below is met to permit movement of milk from within a disease Control Area to processing (during an animal disease outbreak).

- Obtain a National Premises Identification Number (PIN) through the Minnesota Board of Animal Health or call the USDA area office at 651-234-5680.

- Conduct on-farm disease surveillance

- Monitor the herd for FMD (See On-farm monitoring for FMD)

- Demonstrate normal production parameters and no visible signs of disease

- Maintain farm visitor/traffic logs

- Keep movement records of animals, people, milk trucks, equipment, and other items on and off of the farm

- Complete Monitored Premises Questionnaire [in Forms + Resources]

- Implement procedures and biosecurity measures for on-farm milk loading (see below and the Biosecurity Plans section)

- Be aware that destination premises must meet the permit criteria for receiving milk.

On-farm Milk Loading Procedures and Biosecurity Standards

Prior to an FMD outbreak, the checklist below, along with the corresponding milk movement Biosecurity Performance Standards (BPS), may be used as guidance by the Biosecurity Manager to develop an operation-specific, written, Enhanced Biosecurity Plan for On-Farm Milk Loading. This list summarizes the recommendations; links to supporting materials are provided throughout. Templates for an enhanced biosecurity plan for on-farm milk loading may be found in the Biosecurity Plans section.

An alternative to this checklist and/or the biosecurity plan template is a livestock farm planning database currently in development. A link will be posted as soon as it is available.

Once the biosecurity plan is written, dairy farm owners/managers may use the checklist in the following ways:

- In the absence of FMD in the United States, dairy farm owners/managers should plan for how each item will implemented (supplies needed, changes in management practices, etc.).

- During a disease outbreak and if the dairy operation is located in an FMD Control Area, Responsible Regulatory Officials will likely require that these procedures and biosecurity standards for on-farm milk loading be implemented before raw milk movement to processing is permitted.

If FMD is diagnosed anywhere in the U.S., it is strongly recommended that dairy farm owners/managers immediately implement items in the FMD Prevention Biosecurity Plan as applicable to their operation to minimize the risk of their animals being exposed to FMD. See the Biosecurity Plans section for more information.

Biosecurity Manager

The Biosecurity Manager is identified for the operation. This individual:

- Is responsible for developing the written biosecurity plan with the assistance of a veterinarian (if they are not a veterinarian).

- The plan is reviewed at least annually and whenever the operation goes through a change that affects biosecurity.

- Ensures biosecurity training at least annually of all individuals who work at the operation, as well as access to a copy of the plan.

- Has the written authority to ensure compliance with biosecurity protocols and take corrective action as needed.

Procedures and Biosecurity for Milk Loading

- Line of Separation (LOS)

The biosecurity plan includes an LOS, which is an outer control boundary to separate off-farm traffic from on-farm movement of vehicles, people, and animals - and thus limit exposure of susceptible animals to disease. (See LOS options for milk collection and Determining LOS)

- The LOS is clearly defined in the biosecurity plan and is clearly marked on the premises.

- The milk truck and hauler/driver only cross the LOS if indicated in the Biosecurity Plan

- Through a clearly marked and controlled LOS Access Point.

- Following appropriate biosecurity measures.

- Milk Collection

The milk hauler/driver follows the farm-specific standard operating procedures that meet or exceed the milk movement Biosecurity Performance Standards (BPS).

- The plan indicates which Line of Separation (see below) scenario the farm is implementing:

- Milk house is outside the Line of Separation (LOS)

- Only the transfer hose crosses the LOS

- The milk truck and hauler/driver cross the LOS

- The producer clearly communicates farm-specific milk loading procedures and biosecurity standards to milk hauler/driver (hauling company).

- The plan indicates which Line of Separation (see below) scenario the farm is implementing:

- LOS Access Point

If the milk truck and hauler/driver cross the LOS, entry is restricted to a controlled LOS Access Point.

- This LOS Access Point is protected with a suitable barrier (e.g., gate, cable, rope) and is clearly marked with a sign in language(s) understood by all entering.

- The milk truck is cleaned to remove visible contamination and then disinfected prior to crossing the LOS.

- The milk hauler/driver moving through the LOS Access Point follows specific biosecurity steps.

-

Cleaning and Disinfection (C&D) Station (if needed)

If the milk truck and hauler/driver cross the LOS, there is a clearly marked cleaning and disinfection (C&D) station with the means to remove visible contamination and then disinfect the truck. (See Milk tanker C&D)

- The C&D station is operated by individuals who have received documented training in proper use of personal protective equipment and the principles of C&D.

- Follow label instructions when using disinfectants and ensure that runoff does not enter waterways, animal housing, or on-farm traffic areas.

- The biosecurity plan contains contingency plans for vehicle and equipment C&D in inclement weather.

Receiving/Processing Plant

The producer is aware that the receiving/processing plant meets the permit criteria for receiving milk. This may be communicated through the milk marketing agency.

Farm Visitor/Traffic Logbook

All foot, vehicle, animal, and equipment traffic on and off of the dairy premises is recorded in a logbook. (See Farm visitor/traffic log book)

- The logbook is monitored by an individual working on the dairy to ensure accurate completion.

- The contact information and work schedule records for all workers are maintained.

On-farm monitoring for FMD

The dairy farm has a Cattle Health Monitor, and all dairy personnel who work directly with the animals are trained to recognize the signs of FMD. (See On-farm monitoring for FMD)

- Animals are observed twice daily for signs of FMD.

- Daily observations are recorded in a log book.

- Any abnormal findings are reported to state regulatory officials. This may be through the herd veterinarian or the milk marketing agency.

Communication Plan/Emergency contacts

The dairy producer has a plan in place to communicate with their veterinarian, field representative and/or processor, and other important contacts during an outbreak. (See Communication plan/Emergency contacts)

Contingency Plans

In the event that movement off the premises is not allowed, regulatory officials must provide guidance and approve of plans for:

- The disposal of bulk tank raw milk

- The disposal of carcasses that would normally be moved off-site

Supporting materials

LOS Options for milk collection

Determining the LOS

Milk tanker C&D

Farm visitor/traffic log book

On-farm monitoring for FMD

Communication plan/Emergency contacts